Boron in desulfurization wastewater from a thermal power station is removed using a flocculant | Additional information about adsorbents

Contents

1.The place of “READ-CX” flocculants for water treatment used to treat boron

2.About water treatment of boron

4.Comparing “READ-CX” flocculants for water treatment with a conventional method

4-1.Effects of different chemicals on liquids simulating desulfurization wastewater

4-2.Comparing “READ-CX” flocculants for water treatment with a conventional method (aluminum sulfate)

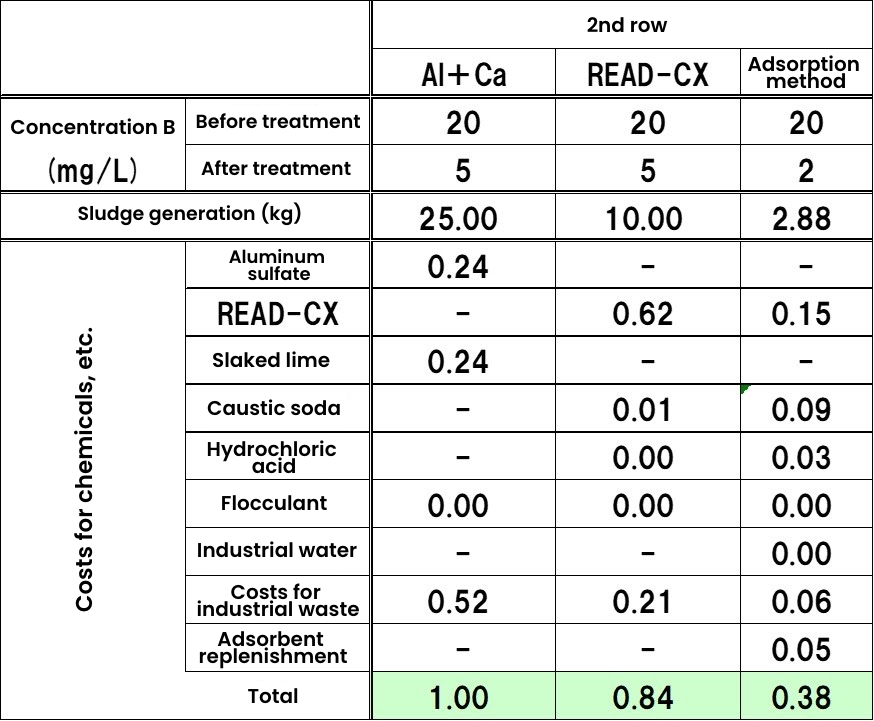

5.About the running costs for the flocculation treatment of boron

6.Combined treatment with an adsorbent reduces treatment costs

The place of “READ-CX” flocculants for water treatment used to treat boron

Overseas thermal power stations

About water treatment of boron

An excessive amount of boron can adversely affect the growth of plants. If continuously ingested, even at a low concentration, boron may reportedly cause the deterioration of reproductive function or other health problems in the human body. Technologies for treating boron-containing water include the vacuum evaporation and solidification, membrane separation, coagulating sedimentation (using aluminum sulfate and slaked lime), coagulating sedimentation (“READ-CX”), adsorption and a combination of these methods.

The following describes an example of Air Water Group “READ-CX” flocculant being used to treat boron-containing desulfurization wastewater at overseas thermal power stations to fulfill the targets established in environmental regulations.

Example of boron treatment using “READ-CX” flocculants for water treatment at overseas thermal power stations

It was necessary for overseas thermal power stations to treat boron-containing desulfurization wastewater to satisfy the standards related to wastewater regulations.

This led to coagulating sedimentation using Air Water Group “READ-CX” flocculant for water treatment.The target value, 50 mg/L or lower, was achieved.

“READ-CX” works in smaller quantities than the general method and can limit sludge generation. For these reasons, it helped to reduce costs.

Result of treatment using a “READ-CX” flocculant for water treatment

- Treatment concentration: B = Up to 500 → 50 mg/L or less

- Quantity of treated water:500m3/d

Comparing “READ-CX” flocculants for water treatment with a conventional method

Treating boron entails a limitation in methodology and considerable costs. In contrast, “READ-CX” can demonstrate superiority over the conventional method.

“READ-CX" works better than conventional chemicals and enables reduction of chemical addition.

This can reduce sludge generation and also reduce the costs for industrial waste as much.

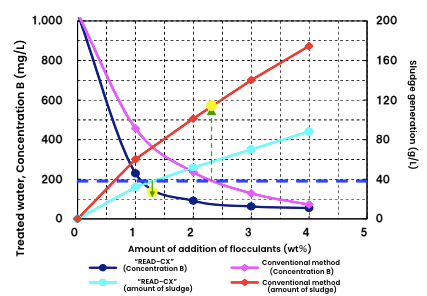

Effects of different chemicals on liquids simulating desulfurization wastewater

Take an example from the following graph. If the treatment target is 200 mg/L, the conventional method would consume 2.3 wt% chemicals and generate 115 g/L sludge. With the same target, “READ-CX” can reduce the use of chemicals to 1.2 wt% and sludge to 38 g/L, which means reducing chemical addition and sludge generation to half and to one third, respectively.

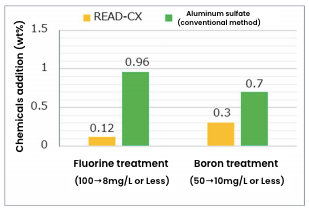

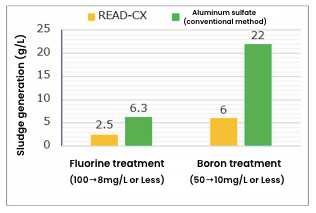

Comparing “READ-CX” flocculants for water treatment with a conventional method (aluminum sulfate)

Aluminum sulfate, an aluminum chemical, is commonly used to treat boron or fluorine. The following data compares this method with “READ-CX”.

The conventional method would require about 0.7 wt% of chemicals to be added to treat 50 mg/L of boron to the 10 mg/L level. This generates 20 to 25 g/L of sludge.

In contrast, “READ-CX” achieves the same goal at about 0.3 wt% while reducing the sludge generated to about 6 g/L. This is nearly halving the amount of chemicals added and reducing the amount of sludge generated to nearly one third.

using “READ-CX” and the conventional method

using “READ-CX” and the conventional method

About the running costs for the flocculation treatment of boron

Compared to conventional methods, “READ-CX” tends less sludge generation due to the reduced amount of chemical injection, resulting in lower costs.

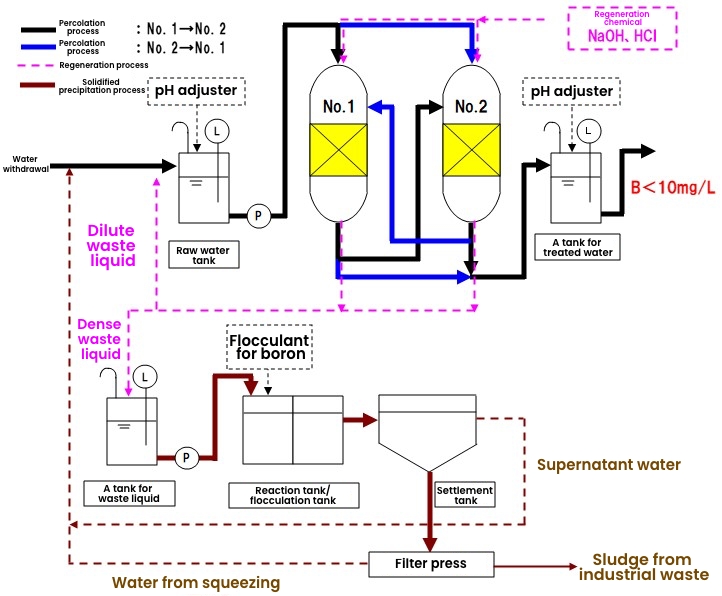

In the adsorption method, recycled waste liquids must be separately treated using solidified precipitation, but this involves only a concentrated material, which results in a significant improvement in terms of cost.

The running costs for treatment where the concentration B is 30 mg/L, 200m3/d (10m3/hr) is as follows (assuming the cost of treatment by aluminum sulfate and slaked lime is 1).

Combined treatment with an adsorbent reduces treatment costs

Partly because of its low molecular weight, boron is one of the elements that are very hard to treat.Therefore, the introduction of technology for the treatment of boron is very costly.

The combined use of an adsorbent with a general solidified precipitation method using aluminum sulfate and slaked lime may increase treatment efficiency and lead to cost reduction. Using an adsorbent enables stable treatment. Using solidified precipitation to treat waste liquid while the adsorbent is being regenerated or directly treating it as industrial waste can reduce treatment costs. The key to cost reduction is to effectively combine treatment methods for high and low concentration ranges.

“READ-CX” flocculant for water treatment or “READ-B” adsorbent is recommended for the treatment of boron-containing wastewater.

The method for using “READ-CX” flocculant for water treatment at the thermal power station involves the chemical being added to the target water and performing pH treatment to precipitate the hazardous components as sludge.

“READ-CX” works better than conventional flocculants and can be used for treatment even in small quantities, so it can significantly reduce the amount of sludge generation, a shortcoming of the coagulating sedimentation method.

The optimal pH range for treatment is between neutral and weak alkali, so the pH adjustment after the treatment is easy or unnecessary. This enables users to expect a significant cost reduction.

“READ-CX” is a liquid with good handling properties, so it can also be replaced with ease.

In addition to boron, “READ-CX” can be used to treat fluorine, arsenic, phosphorus, hexavalent chromium, lead and other elements.

“READ-CX” contributes to the reduction of operational costs in industries and facilities such as plating plants, chemicals manufacturing plants and ironworks.

“READ-B” adsorbent for water treatment is highly selective for specific elements, especially boron.

“READ-B” can exhibit high treatment efficiency and contributes to the reduction of operational costs in industries and facilities such as plating plants, glass plants, coal-fired power stations and industrial waste treatment facilities.